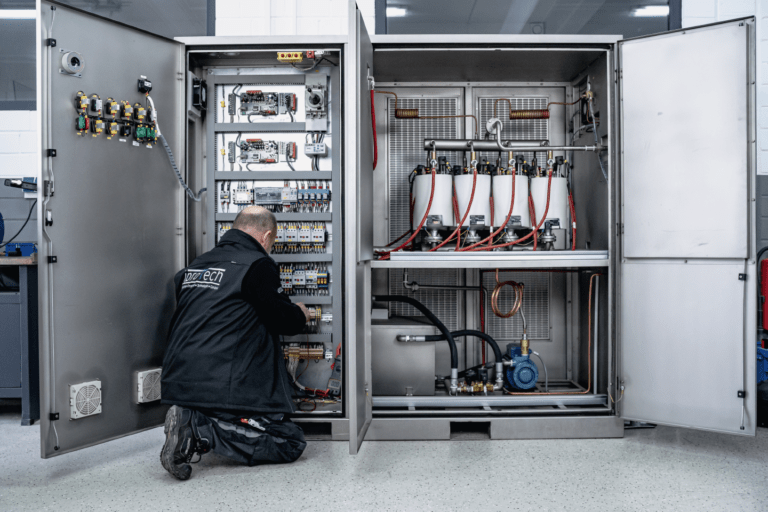

Steam degreasing of metal surfaces – environment-friendly and efficient

Steam degreasing is a sustainable alternative to traditional pretreatment processes for metallic surfaces. Saturated dry steam can be used to reliably remove oil, grease and residues – without harsh chemicals and with minimal water consumption. IproTech systems enable economical and resource-saving cleaning of work pieces before painting, caulking or coating.

Degreasing and cleaning with steam

The degreasing of metallic surfaces is carried out using high-temperature steam with up to 188 degrees Celsius at 12 bar pressure. The heat removes organic residues from the surface without the need for sanding, scrubbing or blasting. The use of chemical cleaning agents can be reduced or completely made up for. If desired, a mild, biodegradable cleaning agent can be added to further enhance the cleaning effect.

Advantages over conventional processes

• Reduction of work steps in pretreatment

• Use of harsh chemicals not necessary

• No impact on sensitive geometries or surfaces

• Fast drying and direct further processing

• Low disposal and operating costs

• Compliance with legal environmental standards (for example, VOC Directive)

• Easy integration into existing production processes

Typical use cases

• Cleaning and degreasing before painting or caulking processes

• Preparation of metal parts for enamelling or powder coating

• Intermediate cleaning in multi-stage production processes

• Oil-free cleaning for hydrogen components and cleanroom applications

Use in various industries

Steam degreasing is particularly suitable for use in the automotive industry, machinery and plant engineering, electrical engineering and surface engineering. The process is also used in medical technology and hydrogen economy, if highest level of cleanliness without chemical residues is required.