Safe, clean and reliable processes through precise dry steam cleaning

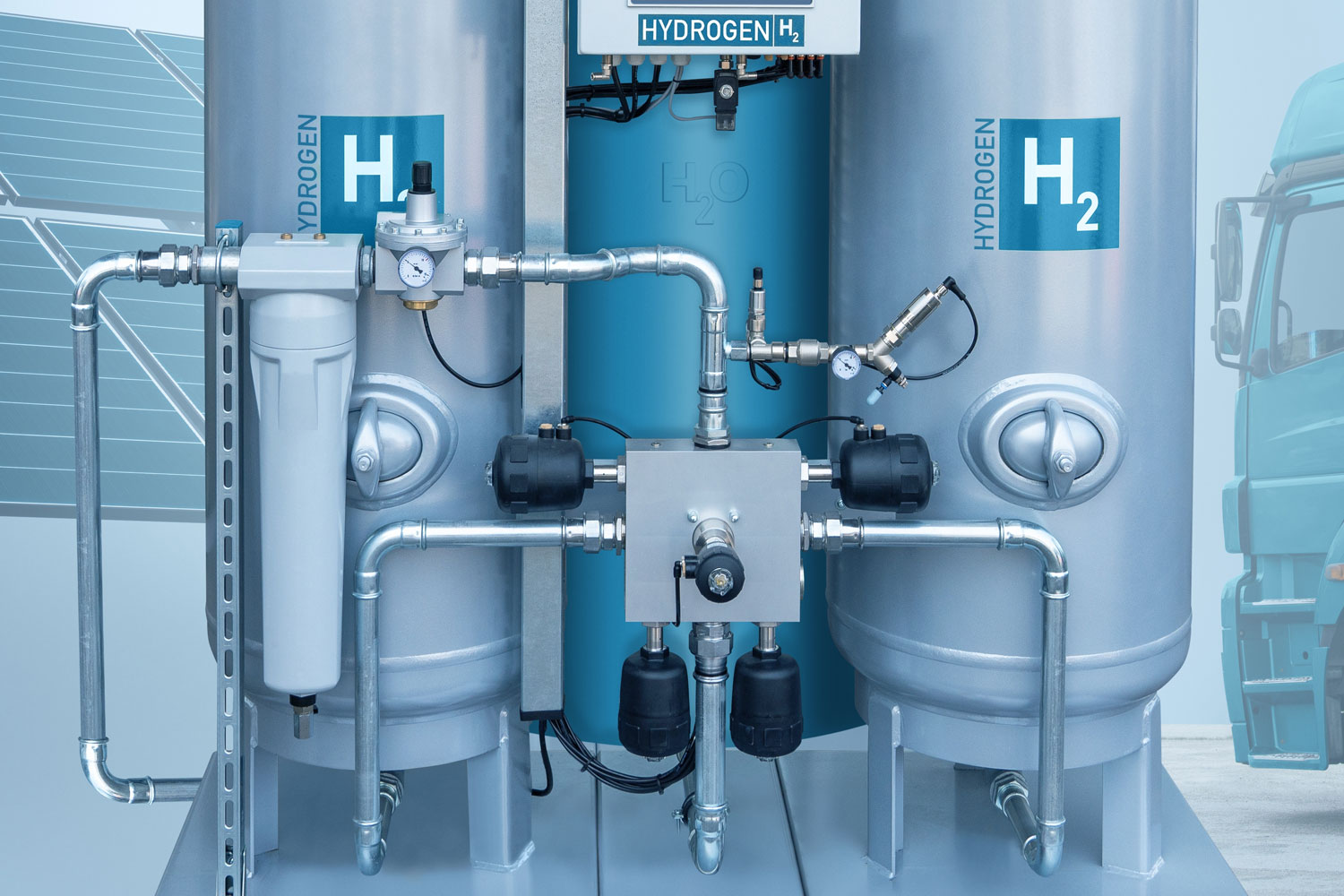

The hydrogen economy demands highest levels of cleanliness, material protection and process stability.

In electrolysers, fuel cells, pressure storage systems or H2 storage tank facilities, even the smallest contaminants can impair the efficiency, safety and service life of components.

Manufacturers and service providers need a cleaning process that is highly effective, gentle on materials and chemical-free.

Typical challenges:

- Fine particles, oil films and dust jeopardise the performance of fuel cells and electrolysers.

- Residues in pipes, valves and compressors can restrain gas flow and compromise operational safety.

- Sensitive membranes and coating layers must be subjected neither to chemical nor mechanical stress.

- High safety requirements demand cleaning that is completely residue-free, dry and compatible with the materials being cleaned.

- Dismantling efforts extend service intervals and lead to costly downtime periods.

- Sustainability requirements demand the use of low-chemical, resource-friendly processes.

Dry steam cleaning – precise, safe and sustainable

Dry steam technology is ideally suited for the high quality and safety requirements of the hydrogen economy.

Advantages:

- Virtually residue-free cleaning of sensitive components such as stacks, valves, pipes, cooling circuits and housings.

- Minimal moisture → no risk of corrosion, short circuits or material degradation.

- Chemical-free process that protects membranes, coatings and seals.

- Cleaning without dismantling several components → shorter downtime periods and faster service.

- Clean process chains for maximum performance, safety and service life of hydrogen systems.

- Resource-efficient and environment friendly, ideal for sustainable future technologies.

This makes dry steam particularly suitable for:

- Manufacturers of electrolysers

- Producers of fuel cells and stack components

- Operators of H2 storage tank stations and distribution networks

- Plant construction firms in the field of H2 compression, storage and transport

- Service providers and maintenance teams for H2 infrastructure