Efficient cleaning for high-grade strip surfaces and stable plant processes

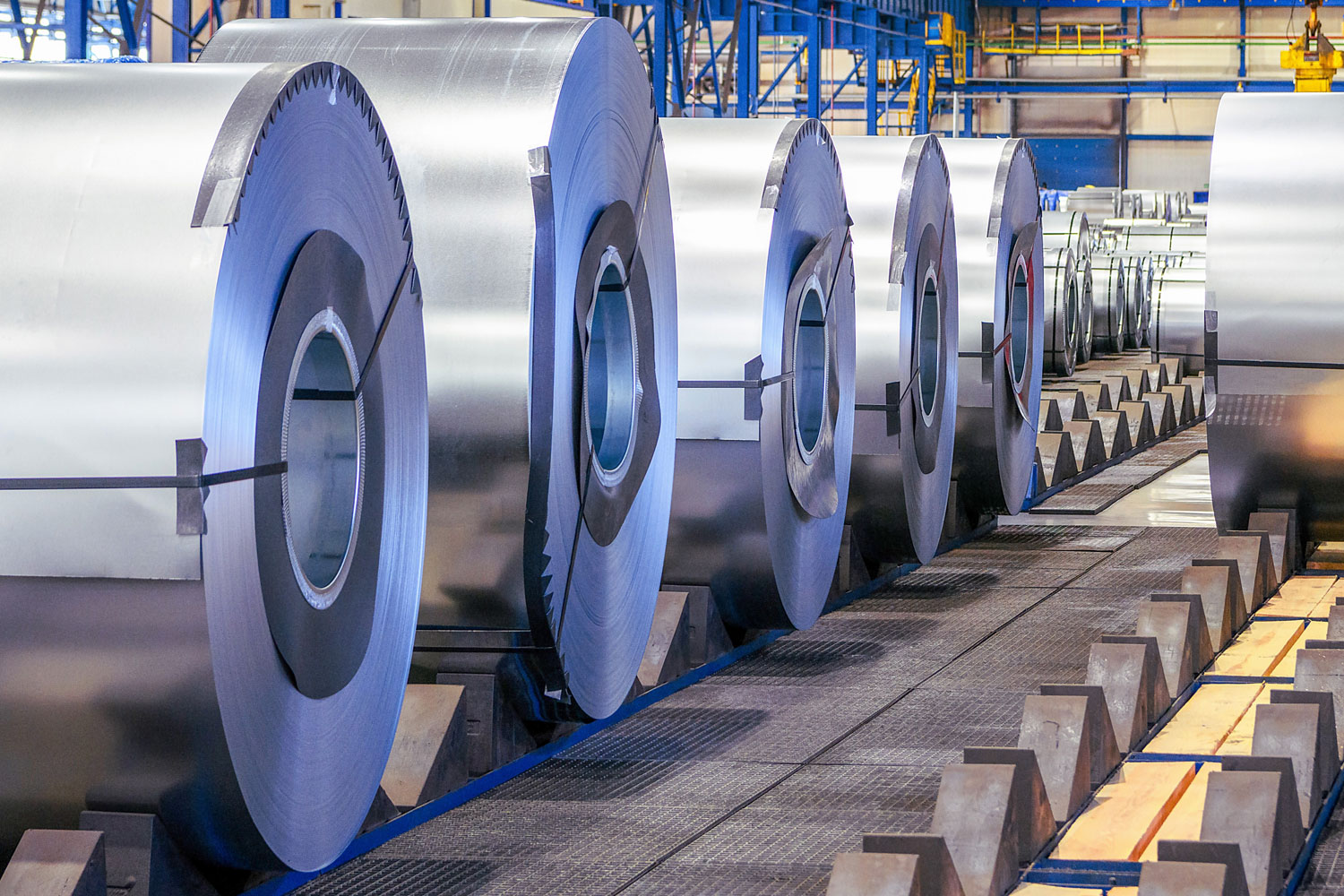

In the coil industry, cleanliness of the plant components is fundamental to the entire production process.

Whether in rolling mills, strip processing or coil coating – oil, abrasion particles, dust or coating residues impair the surface quality of the strip material and increase wear and tear.

At the same time, companies face the challenge to reduce cleaning costs, downtime periods and the use of chemical cleaning agents.

Typical challenges:

- Oil and grease residues on rollers, guides and deflection units, which lead to surface defects.

- Metal abrasion particles and dust particles that can impair sensors, coating installations and process controls.

- Deposits on coating and drying installations that reduce the uniformity of paint layers.

- High downtime periods due to dismantling or manual cleaning processes.

- Chemical-intensive processes that incur high costs and cause environmental pollution.

- Defects in strip material such as streaks, spots or uneven surfaces due to contaminated components.

Dry steam cleaning for maximum quality and process reliability

Using superheated, virtually dry steam, production residues can be removed effectively while being gentle on materials and without chemicals – directly at the facility.

Advantages:

- Clean rollers and guides → fewer surface defects on the strip material.

- Efficient removal of oil, abrasion particles and dust without aggressive chemicals.

- Cleaning without dismantling → drastically reduced downtime periods.

- Improved coating quality in coil coating through residue-free plant sections.

- Protection of sensitive components such as sensors or coating heads due to minimal moisture.

- Lower operating costs due to less chemicals, water and manual labour.

Dry steam cleaning thereby offers significant added value for steel and aluminium coil producers, coil coating companies and strip processing and rolling mills.