High-performance dry steam technology for clean, safe and efficient production environments

Maintenance facilities must repair machines, modules and components in a quick and reliable manner. Thorough cleaning is often the first step in making defects visible, assessing wear and tear and carrying out high-quality repairs on components.

It is a prerequisite for:

secure diagnosis, precise repair, reliable assembly and successful final inspection.

Time pressure, complex component geometries and high quality requirements make this task challenging.

Typical challenges:

- Heavy contaminations such as oil, grease, lubricants, abrasion particles, dust, rust particles or production residues.

- Hard-to-reach components, for example, valve seats, guides, lamellae, sealing surfaces and housing interiors.

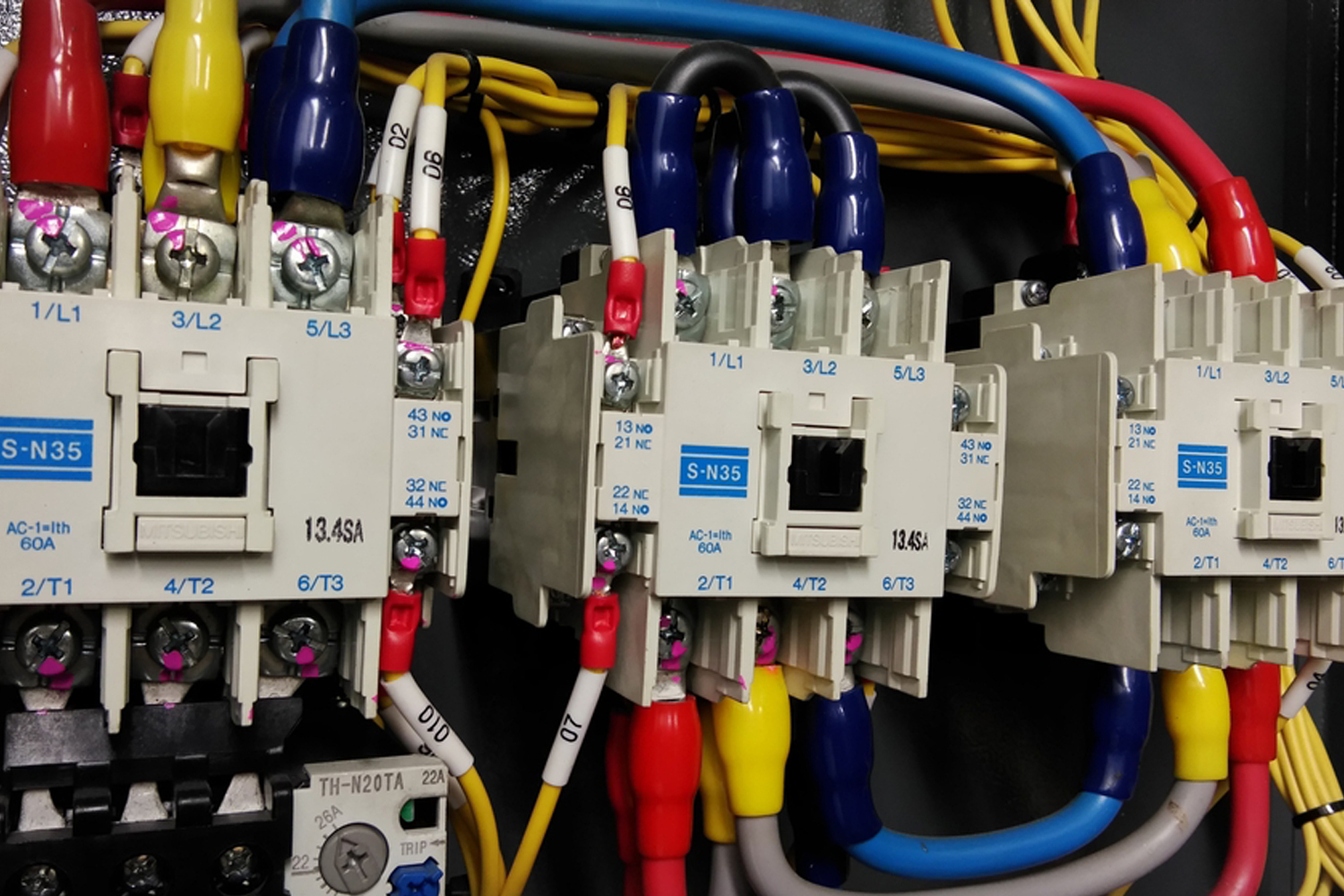

- Sensitive components (electronic systems, sensors, wiring harnesses) that can be damaged by water or chemicals.

- Elaborate cleaning processes that take long working hours and downtimes.

- High-risk or aggressive cleaning agents that can affect surfaces or seals.

- Faulty diagnoses, if components are not thoroughly cleaned.

Dry steam cleaning – precise, safe and ideal for repair and maintenance

Dry steam technology offers significant advantages for maintenance companies:

Advantages:

- Gentle on materials and safe cleaning

No damage to sensitive surfaces

Minimal moisture content – ideal for electrical components and electronic systems - Highly effective removal of stubborn residues

Oil, grease, abrasion particles, coolants, rust stains and particles

Perfect for tight and complex geometries - Faster diagnosis and repair

Wear points, cracks and leaks become visible more quickly

Greater transparency for customers and technicians - Less dismantling

Components can often be cleaned in installed condition

Shorter cycle times and lower personnel costs - Clean work environment & higher service qualityt

Clean components make the assembly & final inspection easier

Professional image of company - Low-chemical and environmentally friendly

No risk to employees, lower costs for disposal, storage and personal protective equipment (PPE).

- Materialschonende und sichere Reinigung

Keine Beschädigung sensibler Oberflächen

Minimaler Feuchtigkeitsanteil – ideal für Elektrik und Elektronik - Tiefenwirksame Entfernung von hartnäckigen Rückständen

Öl, Fett, Abrieb, Kühlschmierstoffe, Rostspuren, Partikel

Perfekt für enge und komplexe Geometrien - Schnellere Diagnose & Reparatur

Verschleißstellen, Risse, Undichtigkeiten werden schneller sichtbar

Höhere Transparenz für Kunden und Techniker - Weniger Demontage

Bauteile können häufig im eingebauten Zustand gereinigt werden

Kürzere Durchlaufzeiten und geringere Personalkosten - Saubere Arbeitsumgebung & höhere Servicequalität

Saubere Komponenten erleichtern Montage & Endprüfung

Professionelleres Erscheinungsbild des Betriebs - Chemiearm & umweltfreundlich

Kein Risiko für Mitarbeitende Weniger Kosten für Entsorgung, Lagerung und PSA

Areas of application in maintenance:

- Machinery and plant maintenance

- Electronic and electric engine repair

- Hydraulic and pneumatic service

- Gear and drive technology

- Industrial mechanics and assembly

- Service & maintenance companies of all branches

Dry steam technology offers clear added value wherever speed, cleanliness and safety are crucial.